Dubai’s construction sector continues to set global benchmarks for high-rise engineering, complex foundations, and fast-paced infrastructure delivery. As buildings grow taller and structural loads become more demanding, traditional lap splicing often fails to meet the technical, safety, and spatial requirements of these mega-projects.

For B2B buyers—contractors, distributors, procurement managers, and wholesalers—understanding mechanical splicing systems is now essential. Whether supplying rebar for raft foundations, core walls, or superstructure columns, knowing the coupler standards and approvals required in the UAE market directly affects project compliance, installation efficiency, and overall structural performance.

In a market where precision, traceability, and time-critical construction are the norm, choosing the right mechanical splice system is no longer optional—it is a strategic advantage.

This guide provides UAE buyers with a practical overview of standards, mechanical requirements, approval processes, and product selection for mechanical couplers in reinforced concrete.

Key Standards Governing Mechanical Splices in Dubai & the UAE

Mechanical splicing systems in the UAE are regulated through a combination of international standards and local compliance frameworks. B2B buyers must ensure that all couplers meet these requirements before use in any Dubai project.

ISO 15835-1 / ISO 15835-2 (International Standard for Mechanical Splices)

The globally recognized reference for couplers used in reinforced concrete.

ISO 15835 specifies:

Requirements for coupler design and performance

Tensile and compression strength criteria

Cyclic (fatigue) behavior for high-demand structures

Manufacturing tolerances and quality assurance

On-site installation and inspection guidelines

Dubai consultants and regulatory authorities commonly refer to ISO 15835 for coupler acceptance.

BS 8110 & BS 4449 (Relevant to Rebar Used With the Coupler System)

While primarily rebar standards, they are relevant because:

The coupler must match the mechanical properties of the rebar

Threads must be compatible with designated grades

Material ductility and chemical composition affect splicing performance

Dubai Municipality (DM) Construction Specifications

DM reviews:

Coupler test reports

Tensile failure mode requirements

On-site threading/installation procedures

Batch traceability and compliance documents

ESMA / ECAS Certification (Mandatory for the UAE Market)

For mechanical splices imported into the UAE, the system must meet:

ESMA product conformity

Factory inspection requirements

Shipment documentation and traceability

Without ECAS approval, mechanical couplers cannot pass customs clearance or consultant approval.

Why These Standards Matter for B2B Buyers in Dubai

Prevents rejection during consultant inspections

Ensures compatibility with local and international project specifications

Protects against failure in high-stress structural zones

Supports better negotiation with mills and manufacturers

Ensures smooth ESMA/DM approval and customs clearance

Reduces structural risk in high-rise and infrastructure projects

Mechanical Performance Requirements for Couplers in UAE Projects

To pass consultant approval and site inspections, mechanical splices used in Dubai must demonstrate specific properties.

Tensile Strength

A compliant coupler must achieve:

≥125% of the specified yield strength of the rebar

Failure must occur in the rebar, not in the coupler itself

This is crucial for safety and long-term performance.

Ductility & Cyclic Performance

Required for:

Seismic-design zones

Tower cores

Raft and pile caps

Couplers must maintain performance under repeated loading cycles.

Fatigue Resistance

Important for:

Bridges

Metro lines

Industrial structures

Systems must withstand long-term stress variation.

Thread Quality and Precision

Threads must be:

Uniform

Full-depth

Free from defects

Poorly formed threads can compromise load transfer and cause failure.

Installation Efficiency

Contractors in the UAE prioritize coupler systems that:

Require minimal labor

Ensure consistent on-site performance

Reduce congestion in highly reinforced elements

Documentation Required for Mechanical Coupler Imports into Dubai

To avoid delays at Jebel Ali, Khalifa Port, or during consultant audits, suppliers must provide:

1. Manufacturer’s Test Certificate (MTC)

Includes:

Chemical composition

Tensile results

Cyclic/fatigue results

Thread accuracy data

Batch/heat number traceability

2. ISO 15835 Compliance Certificates

3. ECAS Certificate (Mandatory for UAE Market)

4. Certificate of Origin (COO)

5. Commercial Invoice & Packing List

Must clearly state:

Coupler size range

Standard used

System type (parallel-threaded, cold-forged, upset, etc.)

6. Third-Party Test Reports (If Required by Consultant)

Issued by accredited international testing bodies.

Clear documentation ensures faster project approval and eliminates compliance disputes.

Common Types of Mechanical Splices Used in Dubai

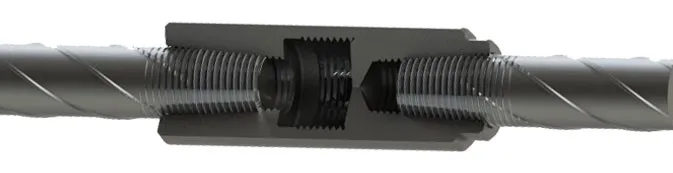

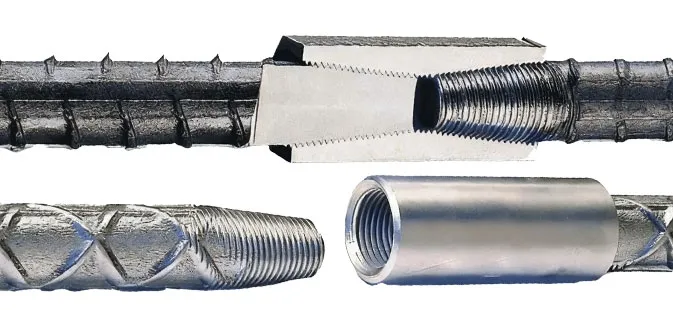

Parallel Threaded Couplers

Most widely used in high-rise towers.

Straight-cut threads

Consistent installation

High structural reliability

Upset Forged-End Couplers

Ideal for:

High-stress zones

Rebars requiring full-strength performance

Position Couplers

Used when:

Two bars cannot rotate

Retrofitting or replacement is required

Transitional Couplers

Connect rebars of different diameters.

Where Mechanical Couplers Are Used in UAE Projects

Mechanical splicing is now standard for:

High-rise columns & core walls

Raft foundations & pile caps

Transfer beams

Mega-infrastructure projects

Congested reinforcement zones

Seismic load regions

Projects requiring minimal lap length

Mechanical couplers help reduce rebar congestion, improve alignment, and enhance structural continuity—key advantages for Dubai’s dense, complex construction environment.