4 Common Causes & Easy Fixes (No Technician Needed)

Have you ever faced this frustrating situation on site?

The rebar is already set, you press the start button, but the motor doesn’t respond at all.

The schedule is tight, sweat is pouring down — and the machine lets you down at the worst moment.

Good news:

In most cases, a rebar thread rolling machine motor that won’t start is caused by simple, common issues.

You don’t need to call a technician right away. With basic checks, many problems can be fixed on-site.

Below are 4 high-frequency causes and step-by-step solutions, explained clearly even for beginners.

01. Safety First — Power Off Before Any Inspection ⚠️

Before troubleshooting any issue:

👉 Disconnect the main power supply

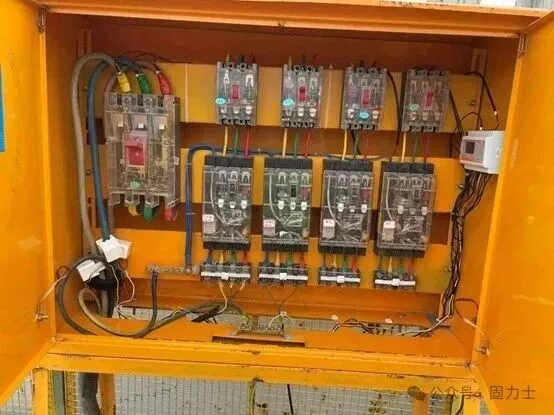

(Unplug the machine or switch off the main breaker in the distribution box)

Thread rolling machines use high-voltage three-phase power.

Electrical repairs without cutting power can cause serious electric shock.

Safety always comes first.

02. 4 Common Causes & How to Fix Them (Step by Step)

❌ Problem 1: Phase Loss in the Power Supply (Most Common & Easily Overlooked)

Why it happens

Rebar rolling machines use three-phase power.

If one phase is missing due to:

Loose wiring

Broken cable

Poor contact in the distribution box

…the motor will fail to start and may even burn the coils if forced.

How to check

Check the indicator lights in the distribution box

Normal: 3 lights ON

Phase loss: 1 light OFF

Use a multimeter (if available)

Normal voltage: approx. 220V per phase

Missing phase: 0V

How to fix

Make sure the power is fully OFF

Inspect the three-phase wires:

Loose terminals

Broken wires

Damaged insulation

Tighten loose terminals

Replace damaged cables with the same specification copper wire

Restore power and test

If all three indicator lights are on, the motor should start normally

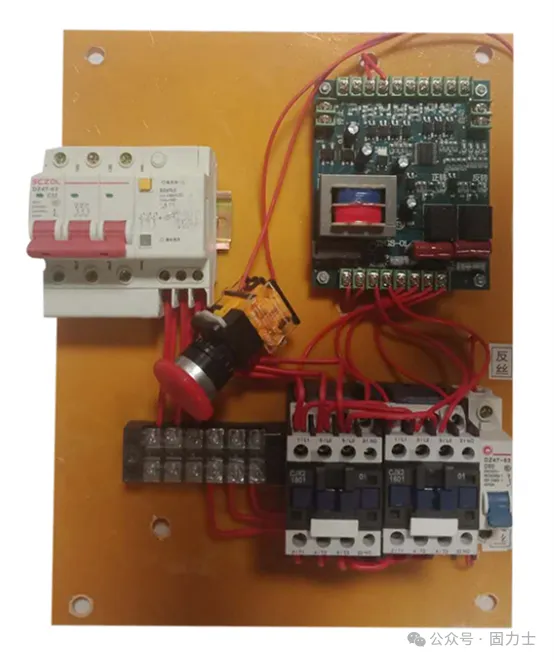

❌ Problem 2: Faulty Start Switch

Why it happens

Over time, the internal metal contacts of the switch can:

Wear out

Burn

Lose conductivity

Typical signs:

No “click” sound when pressing

Button doesn’t return properly

No response from the motor

How to check

Press the switch:

No clicking sound?

Feels loose or stuck?

👉 Very likely the switch is defective.

How to fix

Buy a replacement switch with identical specifications

(Example: 16A / 380V)Take a photo before removing the old switch

(This helps avoid wiring mistakes)Disconnect the old switch

Wire the new switch exactly as shown in the photo

Tighten all terminals securely

Power on and test

❌ Problem 3: Overload Protection Tripped (Motor Self-Protection)

Why it happens

If the motor:

Runs under heavy load for too long, or

Encounters sudden resistance (e.g. oversized rebar)

…the overload protector automatically trips to prevent motor damage.

👉 This is a protection feature, not a fault.

How to check

Look at the overload protector in the control box

If the red button has popped out, it has tripped

Touch the motor housing

It may feel warm (normal after overload)

How to fix

Let the motor cool down for 5–10 minutes

Press the red reset button back in

Reduce the load before restarting

Power on and test again

❌ Problem 4: Mechanical Overload (Rollers Too Tight or Rebar Too Large)

Why it happens

The motor may be “stuck” due to:

Thread rolling rollers adjusted too tight

Rebar diameter exceeds machine capacity

Example:

Machine rated for Φ16–Φ25, but Φ28 rebar is used.

How to check

Power OFF

Try rotating the rollers by hand

Very hard or impossible → too tight

Check rebar size against the machine nameplate

How to fix

Loosen the roller adjustment screw

Turn counterclockwise 1–2 turns

Rotate rollers by hand until smooth

Use rebar within rated capacity

Power on and test

03. Important Final Tips (Very Important)

✔ If you smell burnt insulation or the motor housing is extremely hot,

👉 STOP immediately — motor windings may be damaged.

Call a professional technician.

✔ Always use insulated tools when working on electrical parts.

✔ After repair:

Test the machine without rebar (no-load test)

Confirm smooth rotation

Only then resume normal processing

Final Thoughts

Most motor startup failures are simple, fixable issues — not serious breakdowns.

A calm, step-by-step inspection can save:

Time

Money

Project delays

If you maintain your machine well and avoid overload, it will serve reliably for years.