The GLUS-50KF-Ⅱ Automatic Rib-Stripping and Thread Rolling Machine (hereinafter referred to as the “AGB40 Fast Rolling Machine”) represents the latest generation of high-speed rebar end-processing equipment developed by GLUS.

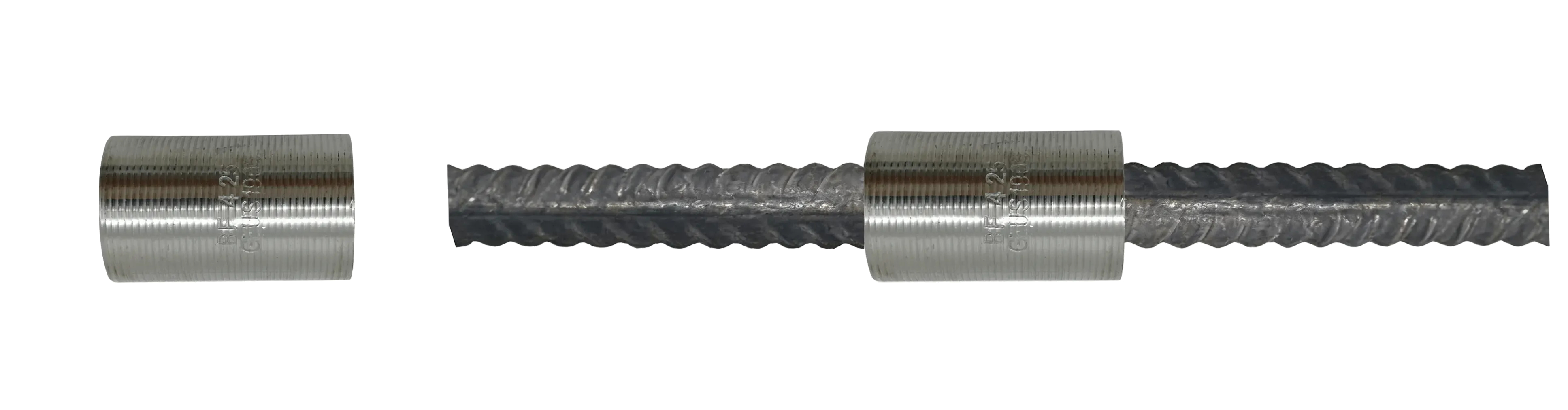

It is specifically designed for the production of parallel-thread rebar ends used in mechanical coupler splicing systems.

By integrating rib removal and thread rolling into a single continuous operation, the 50KF-Ⅱ machine ensures precision, speed, and strength — achieving full mechanical performance equivalent to that of the parent rebar material.

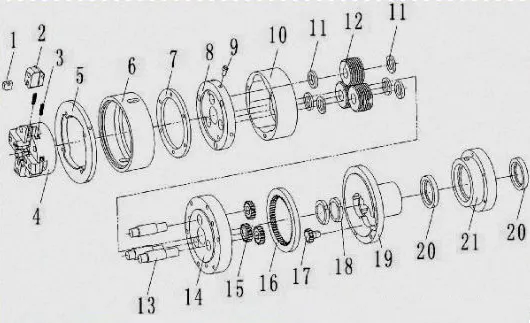

1. Working Principle

The GLUS-50KF-Ⅱ machine performs two sequential operations:

Rib Stripping:

The longitudinal and transverse ribs of the rebar are first peeled off. This process slightly reduces the cross-sectional area of the bar end, forming a smooth cylindrical surface suitable for rolling threads.Thread Rolling:

Three hardened rolling dies simultaneously cold-form the thread onto the stripped section.

Although the bar diameter is slightly reduced during stripping, the cold-working process during thread rolling increases the surface hardness and mechanical strength of the threaded portion.

This ensures that the rebar joint achieves equal or higher strength compared with the parent rebar material.

After the threading process is complete, the threading head expands radially to allow quick retraction of the rollers, enabling rapid cycle times and improved productivity.

2. Applications

The 50KF-Ⅱ machine is suitable for the rib-stripping and parallel thread connection technology widely used in modern reinforced concrete structures.

It can process:

Chinese standard rebar grades HRB400, HRB500, HBB400, and HBB500

Diameters from Ø16 mm to Ø40 mm

Foreign standard rebar after applicability testing

Note: Rebars with deformed or horseshoe-shaped heads are not suitable for this equipment.

Typical Application Areas:

High-rise and supertall building reinforcement

Bridge piers, abutments, and decks

Subway and metro tunnel construction

Industrial and energy infrastructure projects

Precast and modular concrete components

3. Features and Advantages

Dual-Function Design – One-Time Clamping:

A single clamping operation completes both rib-stripping and thread rolling, reducing handling time and ensuring perfect alignment between the stripped section and the thread.Wide Processing Range:

Capable of processing Ø16–Ø40 mm rebar across multiple strength grades, meeting both domestic and international standards.Semi-Automatic Pneumatic Control System:

The machine combines a pneumatic system for automatic feed and retraction with mechanical transmission for power delivery — achieving consistent operation and simplified control.High Efficiency and Precision:

Fast processing speed and smooth workflow.

Thread accuracy unaffected by variations in the original rebar shape or diameter.

Excellent thread form and dimensional precision ensure perfect coupler fit.

Durable and Reliable Construction:

Built with a rigid frame, precision bearings, and high-quality alloy steel rollers, the AGB40 ensures long service life even under continuous operation.Easy to Operate and Maintain:

The structure is simple and the controls are intuitive — allowing new operators to master the process quickly.

Maintenance is straightforward, and consumables (cutters and dies) are easy to replace.High Productivity:

Thanks to the automatic radial release of the roller head, the return stroke is fast, significantly improving overall production efficiency.

4. Technical Summary

| Parameter | Specification |

|---|---|

| Model | GLUS-50KF-Ⅱ |

| Rebar Diameter Range | Ø16–Ø40 mm |

| Applicable Rebar Grades | HRB400 / HRB500 / HBB400 / HBB500 |

| Control System | Pneumatic-assisted semi-automatic |

| Operation Mode | Mechanical transmission |

| Thread Form | Parallel metric thread |

| Process Steps | Rib stripping → Thread rolling |

| Threading Tools | Three-roller cold-forming head |

| Machine Structure | Integrated rib peeling and rolling unit |

| Application Scope | Rebar coupler processing for concrete structures |

5. Operational Notes

The operator must read the user manual thoroughly before use.

Ensure the rebar end is straight and free from deformation before clamping.

Always apply appropriate coolant or lubricant during threading to extend tool life.

Verify thread quality using GO/NO-GO gauges before coupler installation.

Perform regular checks on roller wear, cutting depth, and pneumatic pressure.