The One-Touch Rebar Coupler System represents the next step in fast, tool-free mechanical splicing technology.

Designed for maximum simplicity and on-site efficiency, it allows two reinforcing bars to be joined instantly — simply by inserting the rebar ends into the coupler. No threading, welding, or hydraulic pressing is required.

Inside the compact coupler body, preloaded wedge segments or spring-loaded clamping rings automatically engage with the ribs of the inserted bars, locking them securely in place. The result is a stable, slip-resistant connection that fully meets the performance requirements of Type II mechanical splices under GB/T 50214, JGJ 107-2016, and ISO 15835 standards.

While the unit cost is higher than traditional couplers, the time savings, labor reduction, and ease of use make it ideal for projects where speed and accessibility outweigh equipment or material costs.

1. Principle of Operation

The One-Touch Coupler utilizes an automatic self-locking mechanism activated by the insertion of rebar.

The inner body of the coupler contains conical wedge rings or split grip sleeves that move axially and radially as the bar is pushed in. The rib profile of the bar engages the wedge teeth, creating a positive mechanical interlock that resists both tension and compression forces.

When both bars are inserted from opposite ends, the internal structure ensures equal engagement depth and uniform stress transfer, allowing the two bars to perform as a continuous unit.

Process Steps:

Bar Preparation – Cut rebar ends perpendicular and remove dirt, rust, or oil.

Insertion – Simply push each bar end into the coupler until it locks with an audible or tactile click.

Verification – Confirm both bars have reached the specified insertion depth (typically marked on the bar).

Completion – The splice is ready for immediate concrete placement — no curing, heating, or pressing required.

This one-step process enables rapid installation even in restricted areas such as beam-column junctions, pile caps, and precast connections.

2. System Features and Advantages

Tool-Free Installation

No hydraulic press, threading machine, or power source needed — connections are completed manually.

Ultra-Fast Operation

Each splice can be finished in under 10 seconds, minimizing labor and downtime.

High Structural Integrity

Engineered to meet Type II mechanical splice performance, ensuring full tension and compression capacity equivalent to the parent rebar.

Ideal for Confined or Complex Worksites

Perfect for underground structures, precast element assembly, bridge piers, or retrofitting projects where machinery access is limited.

Consistent Quality

Factory-assembled couplers ensure consistent locking performance and dimensional precision, eliminating operator error.

No Heat, No Noise, No Risk

Completely cold-formed connection — safe for enclosed, hazardous, or environmentally sensitive locations.

3. Coupler Construction and Design

Each GLUS One-Touch Coupler is a precision-engineered mechanical sleeve made from high-strength alloy steel with heat-treated wedge components to ensure long-term durability and grip strength.

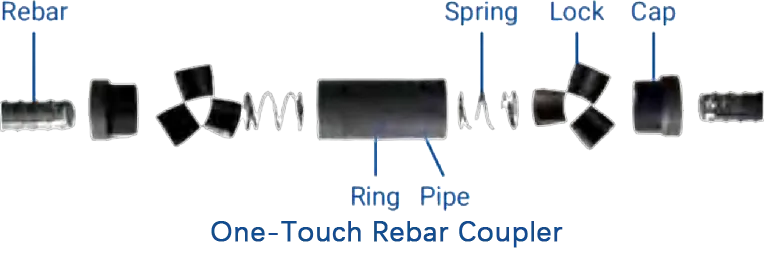

Internal Components:

Outer Sleeve Body: Hardened steel tube for axial load resistance.

Locking Cones / Wedges: Tapered self-gripping segments that bite into the rebar ribs.

Spring / Retainer Assembly: Maintains constant pre-load for secure locking during insertion.

End Caps (Optional): Protect against dust and debris ingress before use.

The internal design provides 360° radial contact and uniform stress distribution, minimizing slippage and local stress concentrations.

4. Manufacturing and Quality Control

GLUS maintains strict manufacturing standards to ensure repeatable connection performance:

Precision machining of inner taper and wedge geometry

Heat treatment and surface hardening for wear resistance

Static tensile and fatigue tests for every production batch

Dimensional checks of insertion depth and locking force

Corrosion resistance tests (salt spray, humidity chamber)

Batch traceability via laser-marked identification codes

All testing is conducted in accordance with ISO 15835 and JGJ 107 specifications for mechanical rebar splices.

5. Applications

The One-Touch Coupler is designed for specialized or time-critical rebar connection scenarios, including:

Confined workspaces (underground shafts, tunnels, bridge piers)

Retrofitting or strengthening of existing reinforced concrete members

Precast concrete assembly and modular construction systems

Remote or temporary sites lacking power or heavy equipment

Emergency structural repair and rapid reinforcement replacement

Its compact form and instant installation capability make it a preferred choice where accessibility and safety are paramount.

6. Conclusion

The GLUS One-Touch Rebar Coupler System offers the ultimate in simplicity and reliability — a zero-tool, zero-thread mechanical splice that transforms the way reinforcement is connected on modern construction sites.

By eliminating complex machinery and multi-step processes, it delivers an instant, full-strength connection suitable for difficult site conditions and high-speed construction needs.

Though its material cost is higher, the dramatic savings in labor, equipment, and time make it one of the most efficient and practical splicing systems available for today’s advanced concrete structures.

GLUS continues to innovate in rebar connection technology — providing engineers and builders with faster, safer, and smarter solutions for the future of construction.