The GLUS-32/40 Cold Extrusion Press Machine is a high-performance hydraulic tool developed for mechanical splicing of deformed rebars through cold extrusion couplers.

It is designed to connect Class II and Class III reinforcing bars (up to Ø40 mm) by applying high hydraulic pressure to deform the coupler, producing a strong mechanical interlock between the bar and sleeve.

Compared with traditional welding or threaded systems, the cold extrusion process offers simpler operation, faster installation, and superior stability, especially on construction sites where electrical power is limited or welding is impractical.

The system is widely used in high-rise buildings, bridges, subways, tunnels, and industrial structures requiring high-strength, full-tension mechanical connections.

2. Principle and Construction

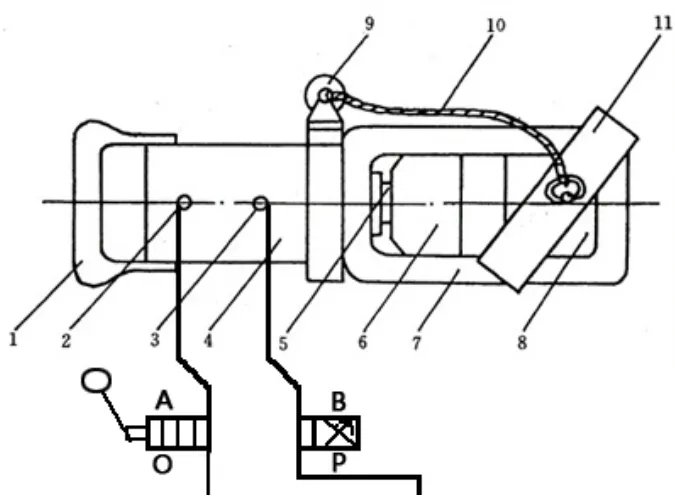

The GLUS-32/40 system consists of two main components:

Hydraulic Press Head (Crimping Unit)

High-Pressure Electric Hydraulic Pump (Power Source)

2.1 Working Principle

The hydraulic pump delivers high-pressure oil to the press head via two hoses — a working line (“A” port) and a return line (“B” port).

When the control valve is in the neutral (unloaded) position, the system circulates oil without pressure.

Switching the valve to the “A” position sends high-pressure oil into the working chamber, moving the moving die forward to compress the coupler and rebar — initiating the extrusion connection.

When the gauge reaches the specified pressure, the valve is switched to the “B” position, allowing oil to flow into the return chamber and retract the moving die.

This cycle is repeated at each crimping point until the entire coupler length is uniformly extruded, forming a permanent cold-worked bond.

3. Purpose and Applications

The cold extrusion process provides a mechanical bite connection between the sleeve and rebar without heat, ensuring that the joint strength equals or exceeds the parent bar.

Suitable for:

Rebar diameters up to Ø40 mm

HRB400, HRB500, and equivalent international grades

Sites with limited electrical capacity

Projects with tight construction schedules or welding restrictions

Typical Project Scenarios:

Power stations and substations

Metro and tunnel projects

Bridges and overpasses

Nuclear, marine, or seismic structures

4. Features and Advantages

Stable and Reliable Connection Quality

Each joint achieves full-strength performance equivalent to the parent bar.

Mechanical deformation ensures a consistent, repeatable interlock unaffected by operator variation.High Efficiency — Three Times Faster Than Welding

The cold extrusion process can improve productivity by more than 300% compared to conventional welding.Simple Operation and Low Training Requirement

The press is easy to operate; workers can become proficient after brief training or by following the manual.No Environmental Restrictions

Unlike welding, the process is independent of weather, humidity, or wind.

There is no open flame, no arc light, and no fire hazard, making it ideal for confined or sensitive environments.Energy-Saving and Cost-Effective

Requires minimal electrical power for the pump motor, reducing site energy consumption.Compact, Lightweight, and Flexible

The press head is small and portable, and when paired with the GLUS high-pressure electric pump, it offers flexible operation suitable for on-site or elevated construction work.Universal Compatibility

Compared with other splicing methods, the cold extrusion system offers strong versatility, low comprehensive cost, and excellent mechanical performance, making it one of the most stable and reliable rebar joint systems in current engineering practice.

5. Operation Method

Set the directional control valve to the neutral position and start the pump.

Install the fixed die and insert the rebar-coupler assembly into the press support frame.

Position the coupler correctly and install the moving die.

Switch the valve to the working position (A) — hydraulic pressure drives the moving die forward, compressing the sleeve.

When the pressure gauge reaches the rated value, shift the valve to the return position (B) to retract the die.

Reposition the press along the coupler for the next extrusion section and repeat the process until all crimping points are completed.

6. Tensile Test and Quality Inspection

To ensure joint reliability, production batches undergo tensile testing in accordance with technical standards:

Sampling Rule:

Each batch of up to 500 identical joints is tested by sampling three specimens (length ≈ 0.8 m).Performance Requirement:

The tensile strength of each joint shall not be less than 1.05 × the specified minimum tensile strength of the parent rebar, or the failure shall occur in the bar body rather than the joint.Re-Inspection:

If any specimen fails, double the number of samples for retesting.

If any specimen in the re-inspection still fails, the batch is rejected.Sampling Source:

Preferably, specimens are taken randomly from actual project joints; if impractical, joints prepared under identical site conditions may be used.

7. Technical Specifications

| Parameter | Specification |

|---|---|

| Model | GLUS-32/40 |

| Applicable Rebar Diameter | ≤ Ø40 mm |

| Applicable Rebar Grades | HRB400 / HRB500 / Class II–III rebars |

| Connection Method | Cold mechanical extrusion |

| Power Source | High-pressure electric hydraulic pump |

| Pressure Type | Double-acting hydraulic system |

| Machine Weight | Compact and lightweight (for mobile on-site use) |

| Operation | Manual directional valve control |

| Environment | All-weather, no fire risk, no arc light |

8. Conclusion

The GLUS-32/40 Cold Extrusion Press Machine provides a robust, efficient, and safe mechanical connection solution for modern rebar splicing applications.

With its stable performance, ease of use, and independence from environmental limitations, it is particularly suited for power-restricted, high-speed, and safety-critical construction environments.

When paired with GLUS cold extrusion couplers, the GLUS-32/40 system delivers uniform, full-strength connections that meet the most demanding structural and quality standards — making it one of the most reliable mechanical splicing technologies available in the global construction industry.