The GLUS Axial Cold Extrusion Machine is a next-generation hydraulic system developed for mechanical splicing of rebars using axial pressure and split-type extrusion couplers.

Unlike traditional radial crimping systems, this model applies axial compression force to deform both sides of the coupler toward the center, achieving a dense, uniform mechanical bond between the sleeve and reinforcing bars.

Designed for Class I and Class II rebars (up to Ø40 mm), the axial extrusion machine provides a stable, full-strength mechanical interlock without heat or threading — ideal for modern construction sites demanding speed, precision, and reliability.

1. Principle and Construction

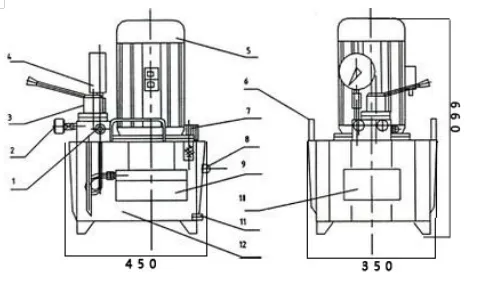

The system is composed of two primary components:

Axial Extrusion Clamp Unit (split-type pressing head)

High-Pressure Electric Hydraulic Pump (energy source)

Working Principle

The hydraulic pump transmits high-pressure oil through dual hoses — a working line (A port) and a return line (B port) — to drive the axial clamps.

When the valve is switched to the “A” position, hydraulic pressure pushes the left and right clamping jaws inward simultaneously, squeezing the sleeve along the axial direction. This causes the sleeve material to flow tightly around the ribbed surfaces of both rebars, creating a strong cold-worked connection.

When the gauge reaches the rated pressure, switching to the “B” position returns the jaws to their initial position.

This process is repeated for each crimping zone until the entire sleeve is securely extruded.

2. Purpose and Applications

The axial cold extrusion process produces a metallic interlock between the sleeve and rebar through cold deformation — ensuring joint strength equal to or greater than the parent bar.

Suitable for:

Rebar diameters up to Ø40 mm

HRB400 / HRB500 and equivalent grades

Construction sites with limited electricity

Projects where welding or threading is not feasible

Typical Applications:

High-rise buildings and bridges

Metro, tunnel, and transportation infrastructure

Nuclear, marine, and seismic-resistant projects

Power stations and substations

3. Features and Advantages

1. Stable, Full-Strength Connections

Each extrusion forms a uniform and repeatable mechanical bond, unaffected by operator variation. Joints can achieve tensile strength exceeding that of the rebar body.

2. High Efficiency and Fast Operation

Compared with welding or threading systems, the axial extrusion method can improve installation efficiency by over 300%, significantly reducing labor time.

3. Simple and Safe Operation

The press uses a manual directional valve with intuitive controls. Operators can achieve professional-quality joints after brief training.

4. Environmentally Friendly and Power-Saving

No heat, arc light, or open flame — ideal for underground, confined, or flammable environments. The pump requires minimal electrical power, making it highly energy-efficient.

5. Compact, Modular, and Flexible

The split-type clamping head design is lightweight and portable, suitable for on-site and elevated operations. It allows flexible extrusion even in narrow spaces.

6. Universal Compatibility

The GLUS axial extrusion system is compatible with a wide range of rebar couplers and diameters, offering a low overall cost, stable performance, and broad engineering applicability.

4. Operation Method

Set the hydraulic valve to the neutral position and start the pump.

Place the axial clamp over the coupler area and fix the rebar assembly.

Switch the valve to position “A” to apply hydraulic pressure and start extrusion.

When the gauge reaches the rated value, switch to “B” to release pressure.

Move the clamp to the next section and repeat until all crimp points are completed.

5. Technical Specifications

| Parameter | Specification |

|---|---|

| Model | GLUS-Axial |

| Applicable Rebar Diameter | ≤ Ø40 mm |

| Rebar Grades | HRB400 / HRB500 / Class I–II rebars |

| Connection Method | Axial cold mechanical extrusion |

| Power Source | High-pressure electric hydraulic pump |

| Pressure System | Double-acting hydraulic |

| Operation | Manual directional valve |

| Machine Design | Split-type clamp, compact and lightweight |

| Working Environment | All-weather, safe, no spark or arc light |

6. Conclusion

The GLUS Axial Cold Extrusion Machine delivers a robust, efficient, and versatile mechanical splicing solution for rebar couplers up to 40 mm.

With its split-type axial clamp, simple operation, and stable high-strength performance, it is particularly suited for power-limited, safety-sensitive, and fast-paced construction environments.

When combined with GLUS axial extrusion couplers, the system ensures uniform full-tension joints, meeting the highest international standards — making it a leading technology for modern structural reinforcement worldwide.