1. Threaded Coupler System

The GLUS Threaded Coupler System provides a full-strength mechanical splice for deformed reinforcing bars, ensuring structural continuity under tension, compression, cyclic, and seismic loads.

Each coupler is precision-machined to match the mechanical properties of HRB400, HRB500, and higher rebar grades in accordance with GB1499.2, JGJ107-2016, ISO 15835, BS 8597, and ACI 439.3R.

GLUS couplers achieve Type I performance classification, meaning that under testing, failure occurs in the bar rather than in the coupler — demonstrating 100% load transfer capability.

2. Rebar Grades and Mechanical Performance

GLUS couplers are suitable for reinforcement grades HRB400, HRB500, and above.

Among these, HRB500 has become the dominant material in modern Chinese and international infrastructure projects due to its higher yield strength, improved ductility, and reduced material consumption for equivalent load-carrying capacity.

The GLUS system ensures consistent mechanical behavior under both static and cyclic loading, making it suitable for high-rise, bridge, and seismic applications.

3. Types of Threaded Couplers

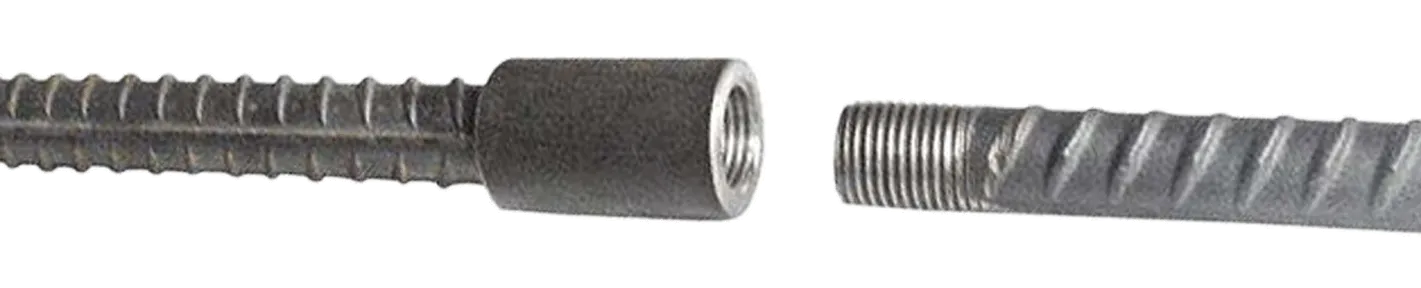

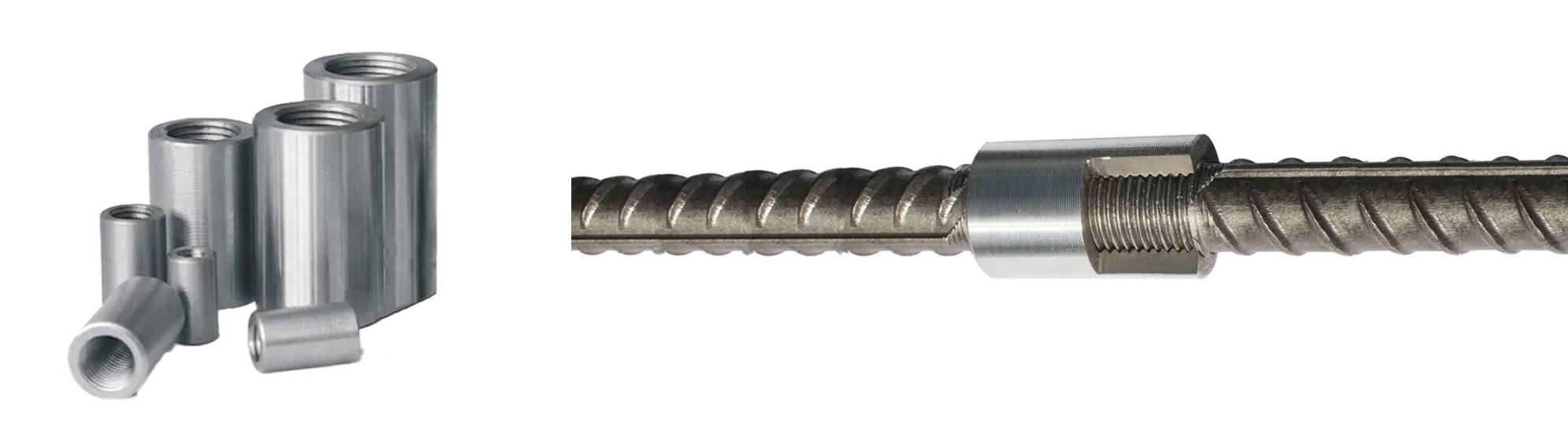

3.1. Parallel Thread Coupler

The Parallel Thread Coupler (commonly referred to in China as the Straight Thread Coupler) is the most widely used mechanical rebar splicing system in the Chinese mainland.

Process: The rebar ends are cut square and machined or rolled to form parallel threads. The coupler is then screwed onto the bars and tightened using a pipe or chain wrench.

Material Efficiency: The parallel-thread coupler is typically manufactured from steel pipe (seamless or thick-wall tubing) rather than solid bar stock. This approach reduces material consumption, simplifies machining, and significantly lowers production costs while maintaining mechanical reliability.

Application: Because of its cost-effectiveness, ease of use, and reliable performance, the straight-thread system has become the mainstream solution for rebar mechanical connections in mainland China and is now being adopted widely in overseas infrastructure projects.

Advantages:

Cost-effective, energy-efficient, and material-saving production.

Full bar-strength performance for HRB500 and higher grades.

Rapid assembly and disassembly; no need for torque calibration.

Ideal for large-scale in-situ construction, precast joints, and bridge reinforcement.

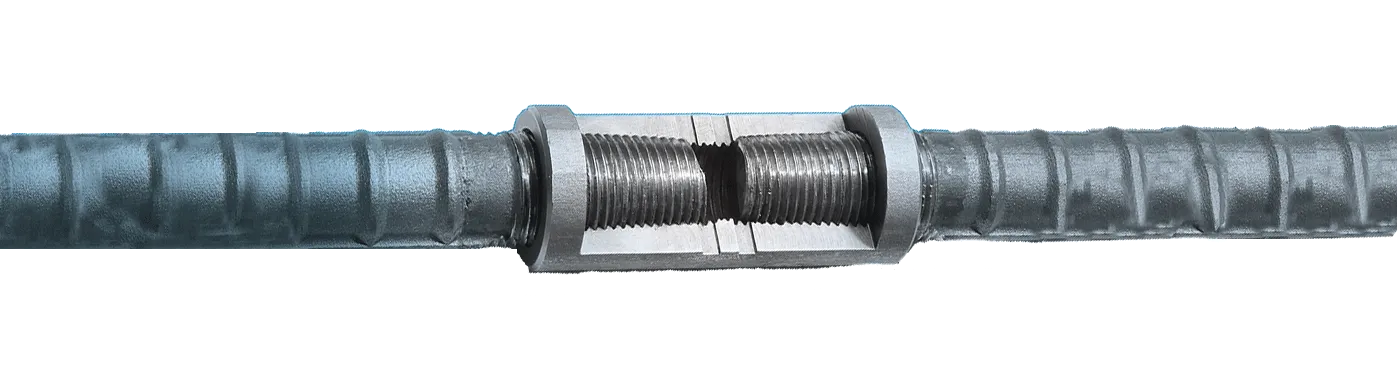

3.2. Taper Thread Coupler

The Taper Thread Coupler uses a conical thread profile on both bar ends to create a self-locking connection when tightened.

Manufacturing: Typically machined from solid steel bar, this process provides high rigidity and precise tolerances but results in higher material consumption and greater machining costs compared to straight-thread couplers.

Performance: The taper geometry produces a wedge action that ensures accurate axial alignment and resistance to loosening under fatigue, vibration, or seismic loads.

Market Status: Although taper-thread systems were historically popular for critical structures such as nuclear, offshore, or seismic projects, their market share in mainland China has gradually decreased. The shift is due to higher production costs and longer machining time, while straight-thread systems now offer equivalent strength and fatigue resistance at a lower price.

Advantages:

Self-locking and self-centering design.

Excellent fatigue and dynamic load performance.

Preferred for specialized applications requiring torque control or tight alignment tolerances.

3.3. Upset Thread Coupler

The Upset Thread Coupler is designed for large-diameter (≥Ø32 mm) or high-strength (HRB500–HRBF600) rebars.

Process: The rebar end is forged (upset) to increase the core diameter before threading, thus preserving the full cross-sectional area of the bar at the thread root.

Performance: The upset process eliminates strength reduction and ensures that the bar fails before the splice, even under high-tension and fatigue loading.

Applications:

Long-span bridges, nuclear containment, seismic columns, and other performance-critical structures.

Advantages:

Maintains or exceeds parent bar tensile capacity.

High fatigue resistance under cyclic loads.

Compatible with automated upset forging lines for mass production.

3.4. Thread Transition Coupler

The Thread Transiton Coupler connects two bars of different diameters (e.g., Ø32 mm to Ø28 mm).

It allows smooth transition of axial stress without the need for additional anchorage or welding.

Each end is threaded to match the respective bar size, and the coupler’s internal bore is tapered to maintain continuous stress flow.

Applications:

Structural joints with varying rebar sizes.

Retrofitting and reconstruction works.

Advantages:

Simplifies on-site detailing.

Ensures full load transfer across bar transitions.

Eliminates mismatched bar cutting or on-site welding.

3.5. Weldable Coupler

The Weldable Coupler provides a hybrid mechanical–welded connection between reinforcement and structural steel.

Design: One end of the coupler has a standard internal thread, while the opposite end features a machined weldable face with chamfered edges to enlarge the welding area.

Connection: The weldable end is fixed to steel plates, embedded inserts, or anchor heads using approved welding methods.

Applications: Precast wall panels, embedded components, composite steel–concrete structures, and bridge anchorages.

Advantages:

Direct, secure bond between rebar and structural steel.

Eliminates need for bar bending or field welding.

Improves connection efficiency in prefabricated systems.

4. Manufacturing and Quality Control

All GLUS couplers are precision-machined using CNC turning centers from high-strength steel such as 45# carbon steel, with optional galvanized, phosphated, or zinc-plated finishes for corrosion protection.

Every production batch is tested under ISO 15835 and JGJ107 requirements, including:

Dimensional accuracy (pitch, length, concentricity)

Tensile and slip resistance tests

Fatigue and low-cycle load tests

Metallurgical structure and hardness checks

Each coupler can be supplied with traceable batch codes, mill certificates, and tensile test reports, ensuring complete documentation for engineering quality assurance.

5. Applications

High-rise buildings and skyscrapers

Bridges, viaducts, and tunnel linings

Precast and modular concrete systems

Power plants, ports, and marine works

Seismic-resistant and energy infrastructure

6. Conclusion

The GLUS Threaded Coupler Series represents the evolution of China’s high-efficiency mechanical rebar connection technology — balancing mechanical reliability with economic practicality.

With the parallel-thread system now dominating domestic and global markets due to its material efficiency and cost advantage, GLUS continues to innovate across all connection types — from upset and transiton to weldable couplers — ensuring robust, adaptable, and standardized solutions for the next generation of reinforced concrete engineering.